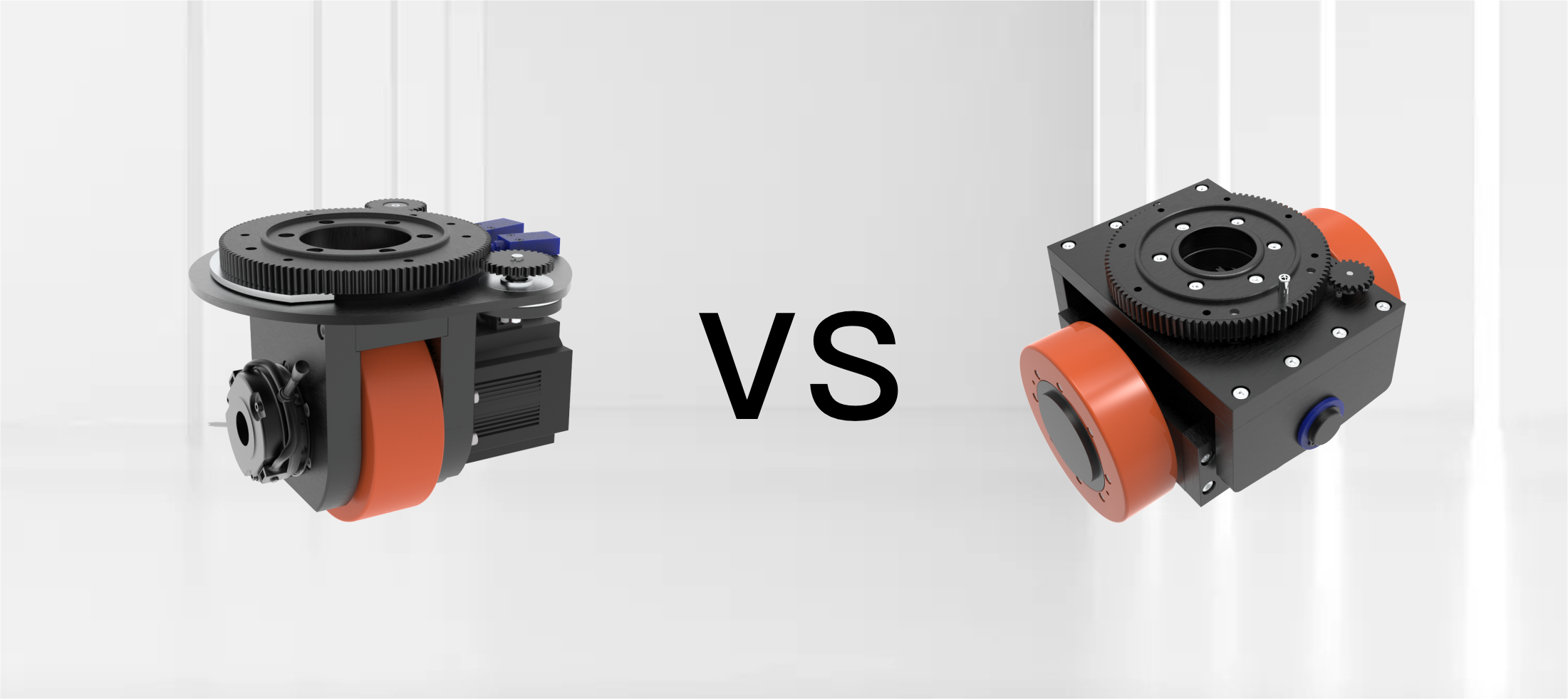

AGV ve AMR şasi tasarımında, direksiyon tahrik sistemleri ve diferansiyel tahrik sistemleri en yaygın kullanılan iki hareket çözümüdür.

Her bir yapı, manevra kabiliyeti, kontrol doğruluğu, sistem karmaşıklığı ve uygulama uygunluğu açısından önemli ölçüde farklılık gösterir.

Uygun tahrik yönteminin seçilmesi, AGV'nin genel performansında kilit bir faktördür.

1. Temel Çalışma Prensipleri

AGV Direksiyon Simidi

Direksiyon simidi, sürüş ve yönlendirme fonksiyonlarını bir araya getirir. Servo motorlar hem direksiyon hızını hem de direksiyon açısını kontrol ederek esnek hareket kontrolü sağlar. Konfigürasyonlar tekli, çiftli veya çoklu direksiyon simidi düzenlerini içerebilir.

Diferansiyel Tahrik

Diferansiyel tahrik sistemleri, birbirinden bağımsız olarak tahrik edilen iki tekerlek kullanır. Direksiyon, her tekerleğin hızının değiştirilmesiyle sağlanır. Bu yapı mekanik olarak basittir ve temel AGV platformlarında yaygın olarak kullanılır.

2. Hareket Kabiliyeti Karşılaştırması

| Bakış açısı | AGV Direksiyon Simidi | Diferansiyel Tahrik |

|---|---|---|

| Yönlendirme Yöntemi | Servo kontrollü direksiyon açısı | Hız farkı |

| Pivot Dönüşü | Desteklendi | Desteklendi |

| Yanal Hareket | Desteklenen (çok tekerlekli) | Desteklenmiyor |

| Manevra kabiliyeti | Yüksek | Orta |

| Yol Uyarlanabilirliği | Güçlü | Sabit yollar için uygundur. |

3. Kontrol Doğruluğu ve Kararlılığı

-

Direksiyon Sistemleri

-

Hassas direksiyon açısı geri bildirimi

-

Daha iyi konumlandırma ve yanaşma doğruluğu

-

Tekrarlanabilir hareket gerektiren uygulamalar için uygundur.

-

-

Diferansiyel Tahrik Sistemleri

-

Basit kontrol mantığı

-

Yüke ve zemin koşullarına daha duyarlı

-

Konum hatası uzun mesafelerde birikebilir.

-

4. Mekanik ve Sistem Karmaşıklığı

| Öğe | AGV Direksiyon Simidi | Diferansiyel Tahrik |

| Mekanik Yapı | Daha karmaşık | Basit |

| Kontrol Sistemi | Çok eksenli koordinasyon | Temel hareket kontrolü |

| Maliyet Seviyesi | Orta ila yüksek | Daha düşük |

| Sistem Entegrasyonu | Yüksek esneklik | Kolay entegrasyon |

5. Tipik Uygulama Senaryoları

Direksiyon sistemleri şu durumlarda tercih edilir:

-

Sık sık dönüş ve hassas yanaşma gerektiren depo AGV'leri

-

Yüksek konumlandırma hassasiyetine sahip üretim hatları

-

Alan kısıtlı ortamlar

-

Orta ve ağır yük taşıma kapasitesine sahip AGV'ler ve AMR'ler

Diferansiyel tahrik sistemleri şunlar için uygundur:

-

Basit ve sabit rotalara sahip AGV'ler

-

Hafif yük veya düşük hızlı uygulamalar

-

Maliyet duyarlı ve standartlaştırılmış projeler

6. Seçim Yönergeleri

Dikkate alınması gereken temel faktörler şunlardır:

-

Rota karmaşıklığı ve hareket gereksinimleri

-

Konumlandırma ve yanaşma doğruluğu

-

Araç yük kapasitesi ve işletme hızı

-

Kontrol sistemi kapasitesi

-

Maliyet ve ölçeklenebilirlik gereksinimleri

Modern depo ve endüstriyel AGV'lerde direksiyon tahrik sistemleri giderek daha fazla kullanılmaktadır.

Çözüm

Hem AGV direksiyon sistemi hem de diferansiyel tahrik sisteminin kendine özgü avantajları vardır.

Diferansiyel tahrik sistemleri sadeliğe ve maliyet verimliliğine odaklanırken, direksiyon simidi sistemleri daha fazla esneklik, hassasiyet ve ölçeklenebilirlik sunar.

Doğru çözümü seçmek, AGV'nin amaçlanan uygulama için en uygun performansını sağlar.

Paylaşmak:

AGV ve AMR Sistemleri için AGV Direksiyon Simidi Teknik Genel Bakış

Depo Sistemleri İçin Doğru Palet Konveyörünü Nasıl Seçersiniz?