1. Valor de los servosistemas en los AGV

La tecnología servo permite:

-

Control de precisión de bucle cerrado (posición/velocidad/par)

-

Respuesta dinámica rápida para una dirección y aceleración precisas

-

Alta densidad de par para un diseño de chasis compacto

-

Mayor tiempo de actividad operativa y menores costos de mantenimiento

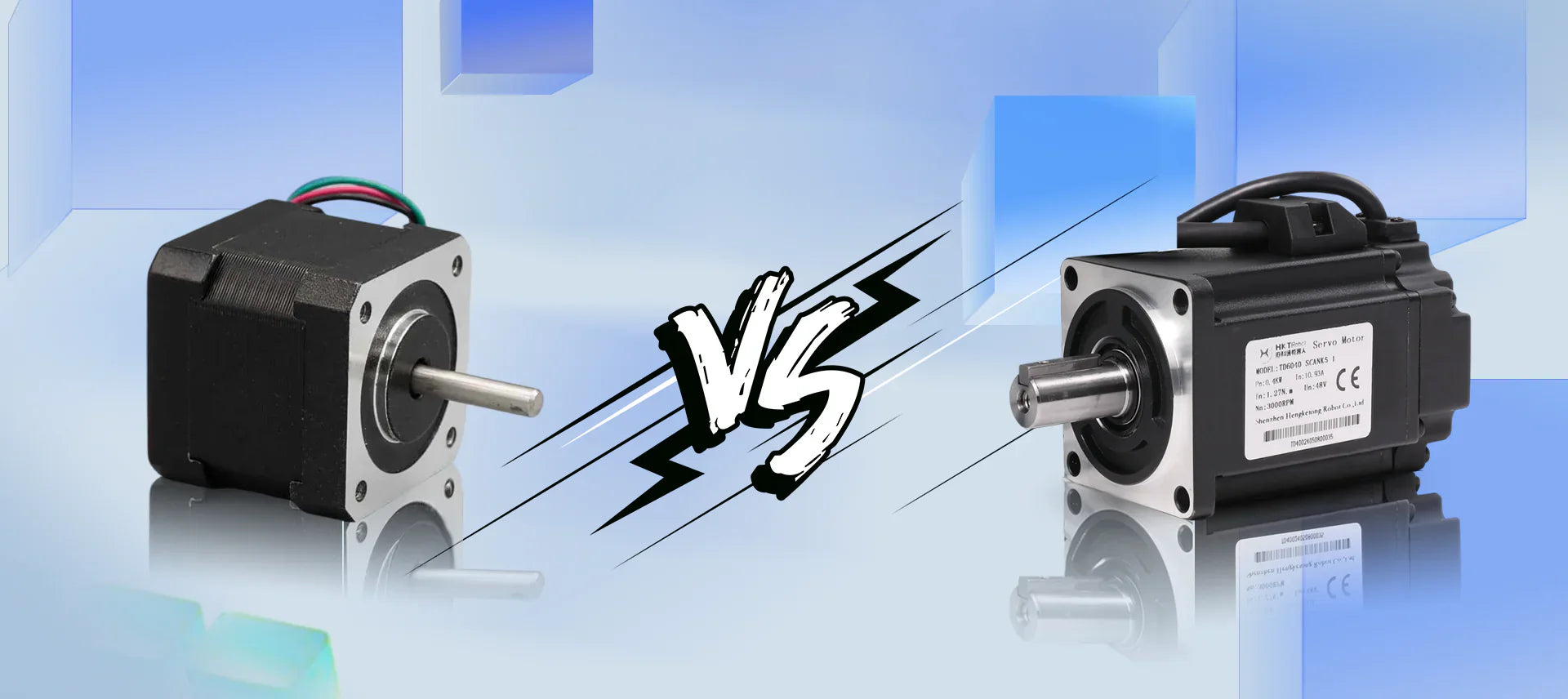

2. Comparación de tecnologías de motores

(La tabla en inglés refleja la versión en chino; se omite aquí por razones de brevedad en la estructura)

Conclusión:

Los servomotores son la opción óptima para AGV logísticos, AMR de servicio pesado y sistemas de transporte.

3. Necesidades estructurales de los AGV

| Sistema | Requisito funcional | Enfoque en el rendimiento |

|---|---|---|

| Ruedas motrices | Tracción + Dirección | Alto par + aceleración rápida |

| Sistema de elevación | Manipulación de carga vertical y giratoria | Fuerte sujeción + densidad de potencia |

| Ruedas giratorias | Apoyando la estabilidad | Diseño compacto y robusto |

4. Fórmulas de dimensionamiento de servomotores

(Ecuaciones idénticas a la versión china)

➡ Recomendación de ingeniería: margen de seguridad ≥20%

5. Curva par-velocidad

-

Estabilidad del par nominal a baja velocidad

-

Alta eficiencia en el rango de velocidad media

-

Zona de limitación de potencia a velocidad extrema

Ideal para paradas y arranques frecuentes y control preciso a baja velocidad .

6. Escenarios de aplicación

-

AGV de almacén: carga útil de 300 a 1500 kg

-

Lanzaderas de cuatro vías

-

Robots móviles de elevación de alta resistencia

(Insertar diagramas/curvas técnicas en el sitio web)

7. Ventajas de nuestros servoaccionamientos

| Ventajas clave | Descripción |

|---|---|

| Control de alto rendimiento | Rechazo de perturbaciones y control de pendientes |

| Compatibilidad con redes inteligentes | CANopen / EtherCAT / Modbus |

| Diseño compacto integrado | Servo + freno + caja de cambios |

| Alta confiabilidad | Límite electrónico + protección contra sobrecarga |

| Personalización completa | Compatible con OEM/ODM |

8. Estrategia de selección

-

Mayor margen de par para pendientes y cargas pesadas

-

Elija EtherCAT para AGV de movimiento crítico

-

Freno magnético para sujeción de seguridad

-

Caja de cambios planetaria compacta para altura de chasis limitada

✅Conclusión

Un sistema de servoaccionamiento bien diseñado mejora directamente:

-

Precisión de navegación

-

Eficiencia del tráfico

-

Ahorro de costes durante el ciclo de vida

Compartir:

Guía de cálculo de potencia del motor: Por qué P=F×V es importante en el dimensionamiento de servomotores y el diseño de movimiento de AGV

Tecnologías clave de simulación de trayectorias de AGV: control inteligente de rutas en la logística de fabricación de automóviles